Advanced Surface Preparation Solutions

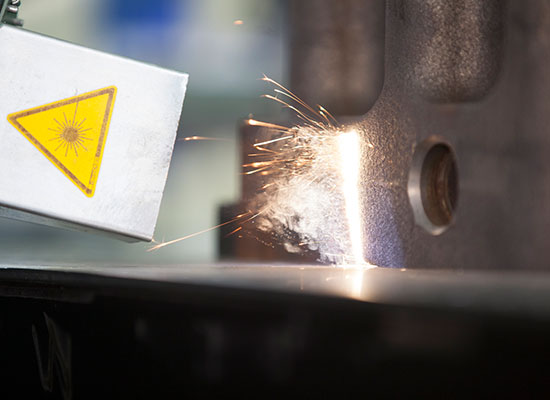

Specializing in custom laser processing solutions, we use advanced pulsed laser technology for superior surface treatment and material ablation. Our solutions efficiently remove tough coatings and contaminants, minimizing substrate damage and enhancing process control.

Benefits Of Using Surface Preparation Technology On Your Materials And Equipment

Versatility

We’re your partner in progress, pushing the boundaries of surface preparation technology to deliver customized, versatile solutions.

Highest Quality Surface Preparation Available

Our superior surface preparation solutions can significantly enhance the durability and performance of materials and equipment, ensuring better adhesion, reducing the risk of corrosion, and extending their overall lifespan.

Low Operating Cost

Our surface preparation technology is easy to operate, and we offer training upon delivery to ensure you get started smoothly.

Low Maintenance

With no consumables, media, chemicals, or leftover residue, our systems require minimal maintenance.

Safer for Employees

Our industrial surface preparation solutions are easy to use, quiet, and highly reliable, promoting a safer work environment.

Environmentally Friendly

Enjoy an eco-friendly process with energy savings up to eight times lower than conventional processes.

Discover How Surface Preparation Solutions Outperform Traditional Methods

How Does Laser Ablation Technology Work

Our surface preparation technology uses laser ablation to remove unwanted materials from surfaces. This method effectively targets rust, oils, paint, and other coatings while preserving the underlying material. It’s an efficient solution for various products across industries—from automotive parts and aircraft paint to heavy-duty coatings on tanks and ships, and even sugar from baking plates.