The AMPP Annual Conference + Expo is coming, and you don’t want to miss out on the largest corrosion and protective coatings event of the year! Get ready for 600+ hours of industry insights, hands-on training, symposia, workshops, meetings, exchanges, poster sessions, and networking.

The AMPP Annual Conference + Expo 2024

WHAT: AMPP Annual Conference + Expo is the largest global corrosion and coatings tradeshow

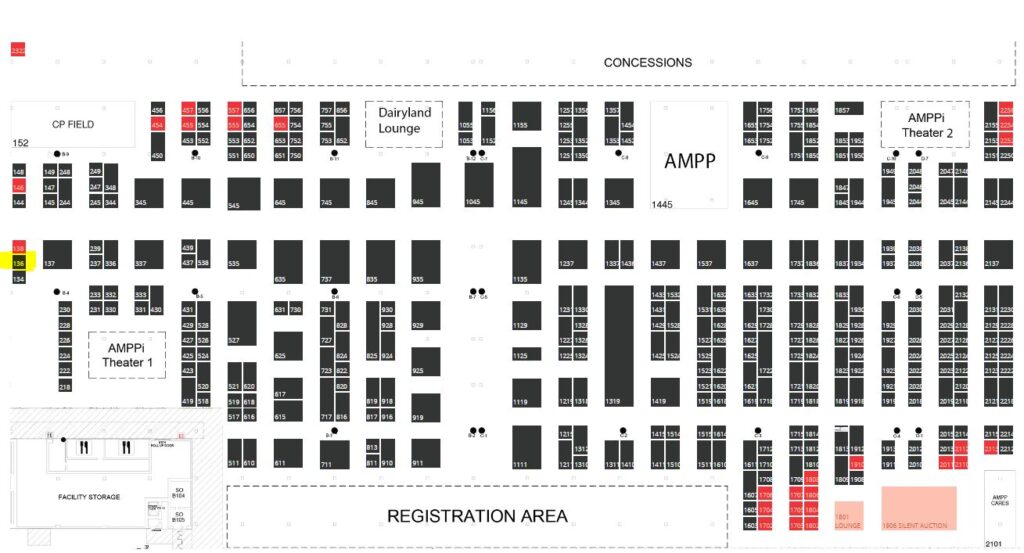

WHERE: New Orleans, LA at the Ernest N. Morial Convention Center —Booth #136

WHEN: March 3-7, 2024

PRESENTED BY: the Association for Materials Protection and Performance

WHAT TO EXPECT

WHAT TO EXPECT

Experience New Orleans with over 6,000 materials protection experts, industry leaders, and tech visionaries at this highly anticipated event offering an extensive program featuring 600+ hours of cutting-edge content.

Engage in enlightening technical sessions led by industry pioneers, stay updated with the latest peer-reviewed research, and explore over 300,000 sq. feet of exhibition space. Listen to the keynote speaker, Dr. Michio Kaku, a world-renowned physicist and author, who will lead an enlightening session on “The Impact of AI on the Workforce”.

HOW TO ATTEND

For information on pricing and all options for Full Conference Registration, One & Two Day Registrations, or Student Registrations visit here.

*Online registration ends on February 29th*

WHERE TO FIND US

Come chat with our sales team at Booth #136.

(Shown to the left side of the “AMPP Theater 1” and the “Registration Area”, highlighted in yellow.)

Next to us, at Booth #134, will be one of our contracting partners, Best-Tec—a lead abatement and environmental decontamination company—who have worked with us recently on two different bridge repair projects for the Department of Transportation (DoT).

LASER ABLATION COATING REMOVAL RECENT USES BY THE DOT

USING LASER ABLATION TO REPAIR BRIDGES

Last year, crews in Connecticut and Virginia used laser ablation coating removal (LACR) to remove corrosion and lead-based paint from bridge I-beams to prepare them for re-painting.

A superior alternative to traditional media blasting, the hand-held laser eliminates the need for worksite containment zones, enabling traffic to flow with minimal disruption.

This solution also improves worker safety, by requiring very little PPE and by eliminating exposure to hazardous materials.

Surface contaminants not vaporized by the laser are collected using a laser fume extractor and 3-stage filter, reducing the hazardous waste by more than 99%.

ADVANTAGES OF LASER ABLATION:

- Provides a clean and contaminant free surface with little or nothing to clean-up.

- Mitigates environmental risks associated with lead paint removal.

- Uses no consumable blast media or chemicals.

- Creates no mixed secondary waste to collect and dispose.

- Does not remove or damage the base metal.

- Does not require dust containment.

- Can be operated near and around other activities using laser safety curtains.

- Operates at a much lower noise level compared to abrasive blasting or needle guns.

- Has a small equipment footprint on-site to eliminate or minimize the need for road closures.

To read more in depth on our project in Connecticut working with the DoT, visit here.

WANT TO LEARN MORE ABOUT LASER CLEANING?

Adapt Laser specializes in providing the highest-quality laser cleaning systems available. Our systems come in both handheld and automated options making them versatile for different coating removal applications and surface preparation. We offer formal laser operations and safety training to ensure both you and your employees get the most out of the laser cleaning system. Our headquarters is in Kansas City, MO but we have sales managers across the country who can travel to your facility for an on-site demo. Over the past 16 years we have equipped numerous companies across varying industries with our state-of-the-art laser cleaning systems.

If you’re looking for a faster, totally unique industrial cleaning and coating removal process, contact us today or call (816) 466-5855 to find the right laser cleaning system for your application.

Like us on Facebook, connect with us on LinkedIn, and subscribe to us on YouTube