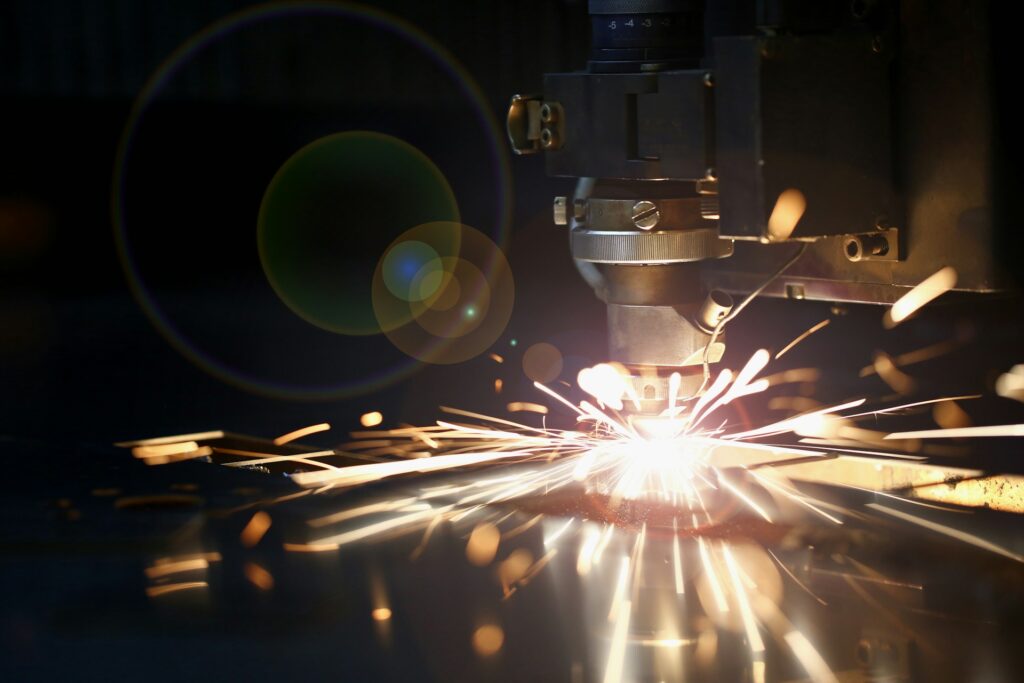

Laser Cleaning vs. Sandblasting: Best for Your Industry?

Choosing the Best Rust Removal Method for Industrial Applications Is your surface preparation process creating more problems than it solves? In industries like aerospace, manufacturing, and defense, the methods used to remove rust or coatings can directly impact part performance, operator safety, and environmental compliance. Choosing the right tool for the job, whether traditional sandblasting […]

How to Choose the Right Laser Rust Removal Tool for Your Shop

Choosing the Right Laser Rust Removal Tool for Industrial Applications Selecting an effective laser rust removal system is key for teams working in aerospace, defense, energy, and other heavy industries. Whether you’re addressing corrosion on significant infrastructure components or cleaning coatings from more delicate materials, having the right laser cleaning setup helps ensure safe, consistent […]

Laser Rust Removal for Aerospace Industry: Essential Facts You Need to Know

In aerospace maintenance, surface damage from outdated cleaning methods can be just as costly as corrosion itself. Whether you’re working with flight-critical components or ground support equipment, maintaining structural integrity without introducing new risks is essential. That’s why more teams are turning to laser ablation, a dry, non-contact cleaning method that removes coatings, rust, and […]

How a Laser Cleaning Company Can Enhance Your Business Operations

Surface preparation plays a central role in long-term equipment reliability and regulatory compliance for industries that rely on clean, bond-ready surfaces, such as aerospace, defense, automotive, and manufacturing. From rust and paint removal to addressing oxidation on sensitive components, more businesses are exploring alternatives to abrasive and chemical-based methods. Pulsed laser ablation offers a non-contact, […]

Significance of Fume Extraction Systems in Laser Ablation Processes

As industries continue to adopt pulsed laser ablation for cleaning and surface preparation, managing the byproducts of the process becomes just as important as the cleaning itself. Fume extraction plays a central role in supporting safe, reliable laser operations by removing airborne contaminants generated during surface treatment. Whether you’re working with metals, coatings, or composites, […]

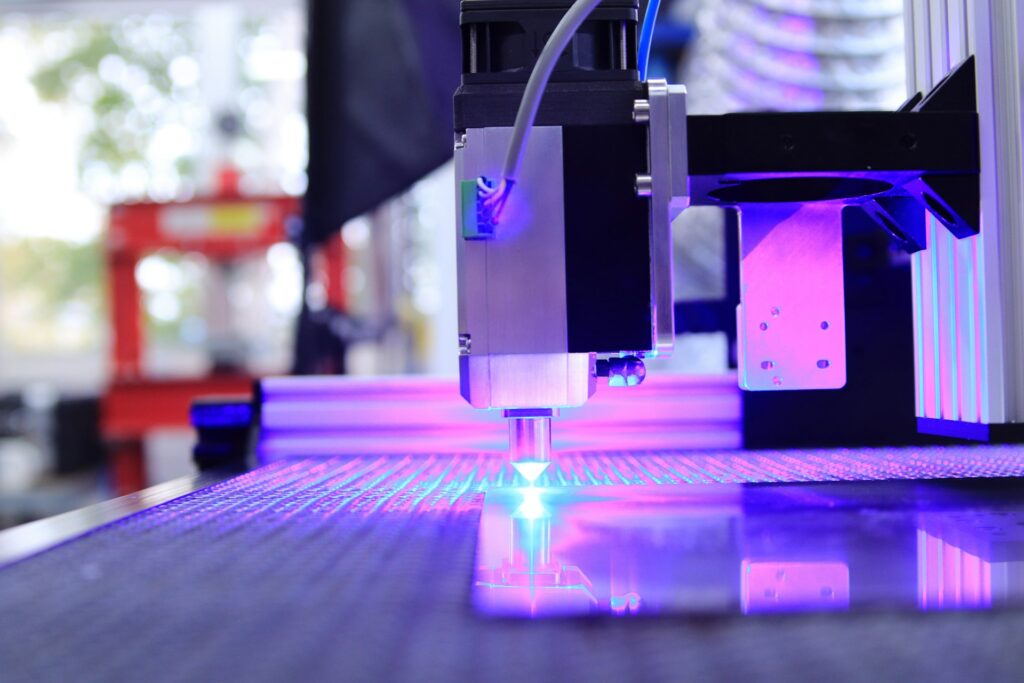

Pulsed Laser Solutions: Enhancing Surface Preparation for Paint Removal

What’s the cleanest, safest way to remove coatings without damaging the surface beneath? Industries like aerospace, defense, and manufacturing face this challenge daily. Traditional methods such as abrasive blasting or chemical stripping can be messy, labor-intensive, and risky to both workers and equipment. That’s why more teams are exploring pulsed laser ablation, a dry, non-contact […]

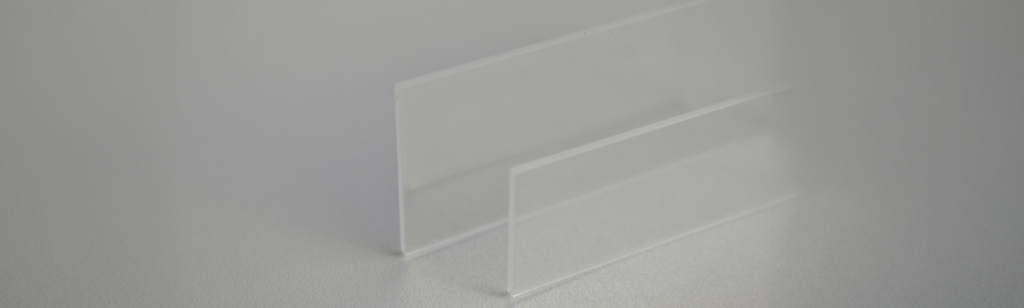

How to Maintain Laser Protection Windows for Long-Term Performance

Even the smallest components play a pivotal role in maintaining system efficiency in pulsed laser ablation and surface preparation processes. The protection window, a critical element of any laser cleaning system, shields internal optics from debris and contaminants during material ablation, ensuring uninterrupted performance. Neglecting this component can lead to issues such as debris buildup, […]

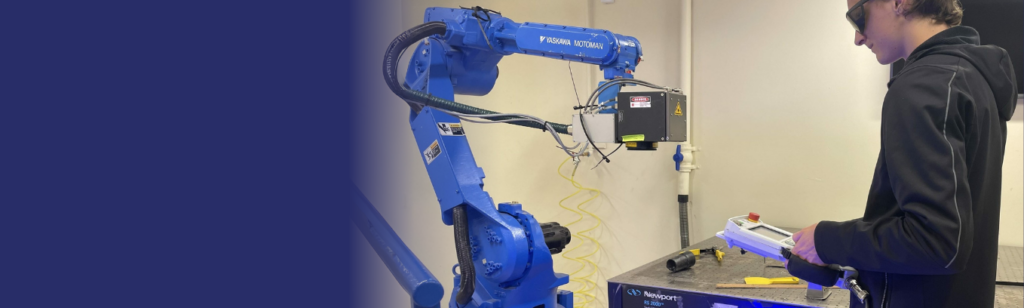

Adapt Laser’s Testing Lab:

Better Surface Preparation Results

“Will it work on our material?” It’s the million-dollar question that precedes any investment in surface preparation technology. For industries where coating adhesion and material integrity can’t be left to chance, the answer requires more than theoretical assurances – it requires proof. Engineers tackle this question daily inside Adapt Laser’s Kansas City testing lab. Surface preparation […]

Fume Extraction Systems for Laser Cutting: Why They Matter

Surface preparation using lasers for rust or paint removal can release fine particulates and airborne contaminants. Without proper filtration, these particles can pose health risks to operators and reduce air quality in the facility. That’s why integrated fume extraction systems are a core part of any laser cleaning setup. Adapt Laser partners with TEKA to […]

How Adapt Laser Supports The

AMPP Standard For Laser Cleaning

Surface preparation on ferrous metals like steel is critical for aerospace, civil infrastructure, and defense industries. Traditional methods often come with challenges – abrasive damage, chemical hazards, and environmental concerns – that impact efficiency, safety, and overall results. The AMPP SP21511-1 standard is a widely accepted framework that defines the structure and terminology for handheld pulsed laser […]