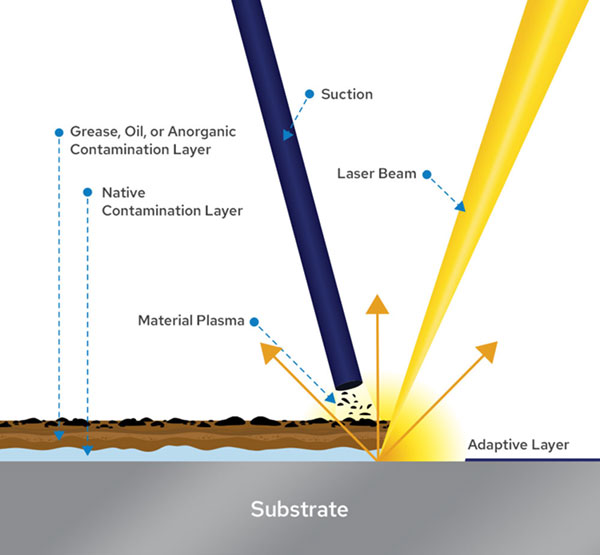

How Laser Cleaning Works

Laser cleaning technology works by sending nanosecond-length pulses of laser light towards a surface. When it interacts with contaminants that absorb laser light, the contaminants or coating particles will either turn into a gas or the pressure of the interaction will cause particles to free from the surface.

With the right laser settings and equipment, laser cleaning is unmatched in its ability to clean all the way to the bare metal of your product. Adapt Laser specializes in the know-how and application of laser cleaning solutions to put together the formula for your specific situation. Once we identify the combination of settings and equipment, the process can be matched across other setups – working very efficiently without affecting the integrity of the surface you are cleaning.

In addition to its cleaning capabilities, laser technology has added benefits: It is easy to operate, safe, easily automated, quiet, and reliable. It doesn’t require cleanup, comes with low operating costs, it’s low maintenance, and environmentally friendly.

BENEFITS OF PULSED LASERS

Pulsed lasers—like the low, mid, and high-power options we offer—carefully remove coatings by storing and releasing energy periodically. This energy is released with a high intensity that can remove coatings like paint by sublimation, vaporization, and concussive detaching.

With Continuous Wave (CW) lasers, energy is released continuously, resulting in a lower intensity. This constant emission doesn’t reach the intensity of a pulsed laser system that’s required for most applications. Low intensity will cause the paint to be removed by incineration instead, often damaging the substrate due to the thermal effect of the process.

Other benefits of pulsed lasers include:

- Less fume and smoke development

- Little heat transfer to substrate

NON-DESTRUCTIVE LASER CLEANING

Lasers with flat top beam profiles spread energy equally over a larger surface area so they clean in a safe and non-destructive manner. This makes them ideal for molds like composite molds that are used thousands of times and require minimal impact to prevent wear and tear.

Lasers with gaussian beam profiles, in comparison, have a higher peak intensity that roughens and damages the surface profile. If used on molds, it could damage the surface and shorten the life of the mold.

Other flat top benefits include:

- Sufficiently cleans and preps surfaces

- Larger spot area decreases process time

WHAT WORKS – AND WHAT DOESN’T?

Laser cleaning is technology that is more effective, safer and superior to traditional methods of cleaning; however, laser cleaning is not infallible. While lasers are ideal to use on most surfaces, there are limitations.

For example, if you need to remove rust, our laser units will do so at a much faster rate than if you had to remove very thick coatings over a large area. By the same token, flat surfaces will experience better results than if you have to clean surfaces with limited line of sight.

This doesn’t mean that laser technology only works on simple tasks. We do provide techniques for complex, 3D surfaces, but removing layers with a thickness of more than 0.5mm tends to not be cost effective. If you have questions about whether laser cleaning is a viable solution for your business, our team is always ready to assist you.

COST SAVING ADVANTAGES

The sticker price of laser cleaners may seem steep at first. However, the investment pays for itself within the first year of use. But you don’t have to just take this statement at face value. When you talk with one of our team members, we can also provide a cost-benefit analysis specific to your organization.

The reasons why purchasing laser technology is a sound investment are several:

- We provide training upon delivery

- User friendly and safe technology

- Easy automation

- Our products are low-maintenance

- Running costs are lower than with a PC desktop

- Available 24/7, year-round

ENVIRONMENTAL ADVANTAGES

In addition to all the benefits to your organization, laser technology is also environmentally friendly. They emit no greenhouse emissions and produce no waste. This is in direct contrast with traditional cleaning methods that may bring forth favorable results for your organization, but are catastrophic for water streams and the Earth’s atmosphere.

By using laser technology, you’ll reap many benefits, including:

- Energy savings (up to eight times lower than with conventional processes)

- No chemicals

- No abrasive components

- Clean disposal

- Safe

- Saving costs by not requiring a full ensemble of protective gear