Anyone who’s been responsible for maintaining critical equipment knows how quickly operations can come to a halt when a key component fails. Whether you’re on a manufacturing floor, working in containment, or overseeing any high-stakes environment, extended downtime is a challenge you can’t afford.

At Adapt Laser, we’re dedicated to advancing the technology that keeps your operations running smoothly. The Quick Swap Fiber technology we offer is a testament to this commitment. By integrating this feature with our state-of-the-art surface preparation systems, we’ve created a solution that drastically reduces downtime, empowers your team, and enhances efficiency across a range of industries.

The Challenge: Managing Downtime

In any industry where laser systems are essential, a fiber optic cable failure can cause significant disruption. Traditionally, replacing a broken fiber and realignment of a new fiber could take over four hours, and that’s if you had an engineer on-site. Often, the process required scheduling a visit, which could mean waiting days for an engineer to arrive, especially if they needed to fly in. This downtime not only stalls operations but also increases costs, with expenses piling up from transportation, lodging, and the engineer’s time.

But what if this process could be simplified? With the Quick Swap Fiber option offered on our lasers it can be. We’ve reimagined fiber replacement, making it faster and straightforward enough for your team to handle without the need for external help. This means no more waiting for an engineer, no added transportation costs, and most importantly, no extended downtime.

The Solution: Quick Swap Fiber Technology

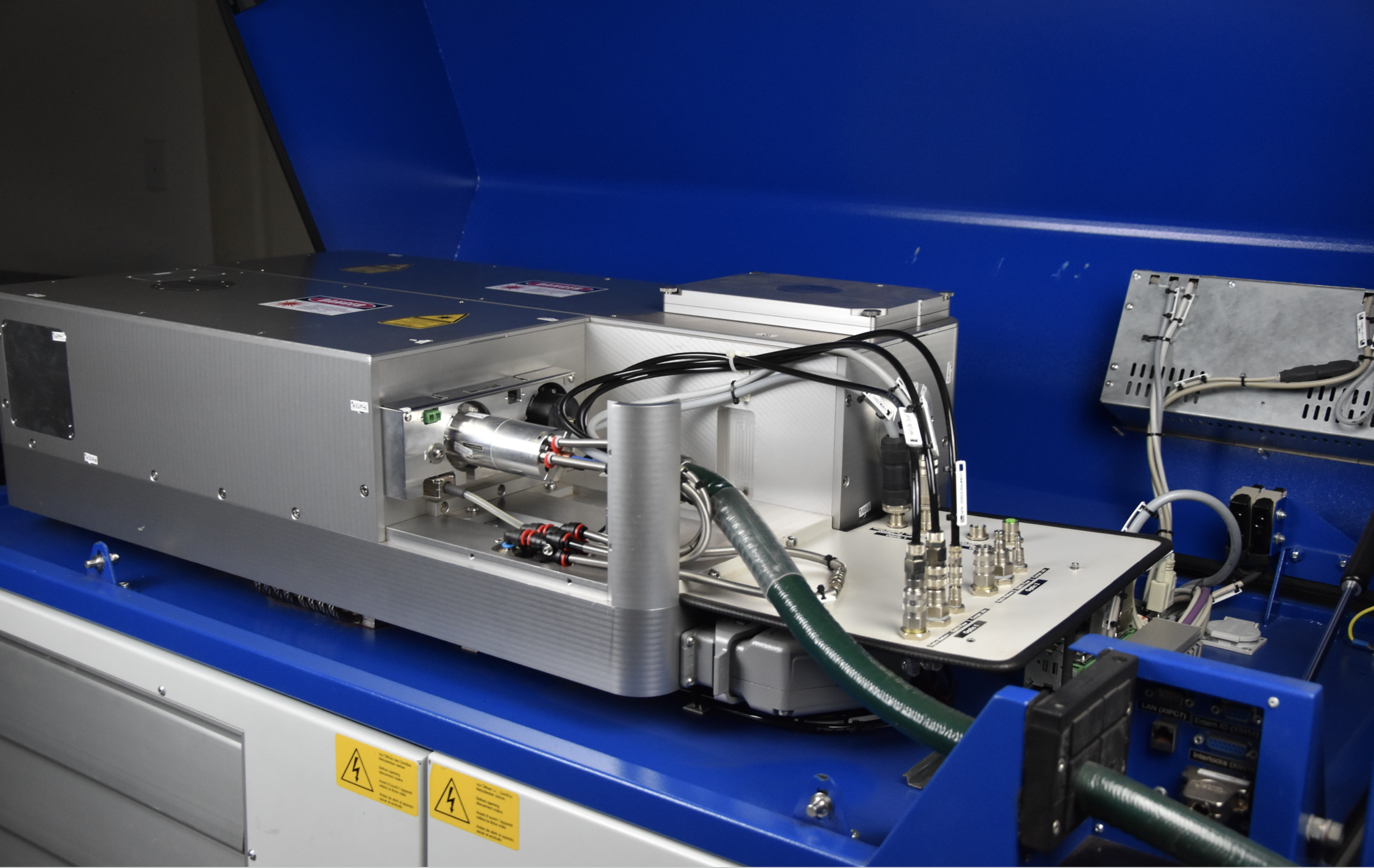

Traditionally, replacing a fiber optic cable involved complex alignments and lengthy downtime. With Quick Swap Fiber, what once took hours now takes just 15 to 20 minutes, and it doesn’t require an engineer.

This technology simplifies what was once a cumbersome process. Your team can now remove the old fiber, connect the new one using precise alignment points, and secure it with the provided torque tools to ensure everything is correctly positioned and functioning. The process is efficient and designed to minimize the risk of errors, empowering your team to manage maintenance with confidence.

Real-World Applications: Manufacturing and Nuclear Industries

Adapt Laser’s technology is designed to meet the specific needs of diverse industries. In manufacturing, where production lines rely on continuous operation, Quick Swap Fiber enables rapid maintenance, getting your production back on track quickly. For the best results, we recommend bundling Quick Swap Fiber with a replacement optic to complete the swap process in minutes.

In high-stakes environments like nuclear facilities or hazardous material handling, the ability to quickly disconnect and replace a fiber optic cable without risking contamination is critical. Quick Swap Fiber keeps your laser systems operational and secure, even in challenging conditions. To further minimize downtime, keeping critical spare parts—such as fibers, optics, and resonators—on hand ensures you’re always ready for a quick swap.

Best Practices for Maximizing Efficiency

For optimal performance and to avoid potential issues, follow these best practices:

- Bundle with a Replacement Optic: For the fastest swaps, combine Quick Swap Fiber with a replacement optic.

- Keep Spare Parts on Hand: Maintain a stock of critical components like fibers, optics, and resonators to ensure quick replacements.

- Adhere to Proper Handling Procedures: Following the training guidelines is crucial to avoid contamination and ensure the longevity of your equipment.

The Strategic Benefits of Quick Swap Fiber

Beyond quick repairs, Quick Swap Fiber offers strategic advantages that enhance long-term efficiency. For industries where safety and contamination control are critical, the ability to replace a fiber without compromising the system’s integrity is invaluable. This keeps your operations safe and functional, even in environments where downtime is costly or dangerous.

Additionally, Quick Swap Fiber is versatile. Whether switching between different fiber and optic combinations or adapting to new operational demands, this technology allows you to respond quickly to changing needs.

Investing in the Future with Adapt Laser

The costs associated with downtime—lost production, delayed processes, and the need to meet safety protocols—make investing in Quick Swap Fiber a smart decision for any industry. While there is an initial investment, the long-term savings in reduced downtime and fewer service calls are clear.

For operations that require continuous uptime, this upgrade is not just a convenience—it’s essential. Being able to perform maintenance quickly and in-house can mean the difference between meeting deadlines and avoiding major disruptions.

Stay Prepared with Adapt Laser

Unexpected issues are inevitable, but with the right technology, you can be ready for anything. By integrating Quick Swap Fiber with Adapt Laser’s advanced surface preparation systems, you’re investing in a solution that empowers your team, minimizes downtime, and keeps your operations running smoothly, no matter the challenges you face.

Ready to learn more? Contact us today to discover how Adapt Laser’s Quick Swap Fiber technology can transform your maintenance processes and minimize downtime in all your critical environments.