NEWEST HANDHELD OPTIC: The effiSCAN

Along with our partners at cleanLASER, we’re continuously using customer feedback and advances in technology to update our laser cleaning systems to make them more operator-friendly and versatile. This extends to our optics, where one area of focus surrounded the size of the optic head itself, and how easy it is to maneuver. We addressed this in the effiSCAN, by designing an ultra-compact head. In order to help prevent operator fatigue, the effiSCAN is also designed to be as ergonomically-friendly and lightweight as possible—without sacrificing on power.

FEATURES

- Integrated E-stop

- Simple-to-change protection window

- Integrated LEDs to illuminate the target surface

- Super compact scanner with a scan speed of up to 40 m/s

- 2-Step safety trigger to prevent accidental beam activation

- Convenient, one-hand operation with the “Touch & Turn” control screen

- Orthogonal fiber optic connection to optimize ablation in hard-to-access areas

BENEFITS

- Lightweight design allows for operator comfort during extended periods of use

- Larger focal area provides significant increases in removal efficiency

- Advanced detection of particles in the suction nozzle promotes optimal operator protection

- Available for cleanLASER systems from CL150 to CL600 (CL1000/ CL2000 pending)

Along with it’s reconfigured head size, the effiSCAN has different attachment and nozzle options to choose from. As with our OSH50 and OSH80 optics, we highly recommend using the nozzle that best aligns with your application in order to achieve the most efficient clean.

ATTACHMENT/OPTIONS:

- Fume extraction nozzle

- Roller nozzle

- Side handle / jig mounting

- Motion Distance Sensor (MDS)

- Removable focusing optics module

WHY IS A COMPACT HEAD IMPORTANT?

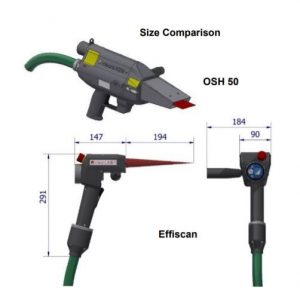

The effiSCAN’s compact optic head gives it the ability to move in and around parts during ablation, in a way that no other existing optic can match. The OSH50 is by no means a clunky optic, but gives the operator a harder time when it comes to focusing and finding an angle that won’t ignite fatigue.

USE IN NUCLEAR POWER PLANTS

Our lightweight effiSCAN optic is now being used in nuclear power plant facilities for safe and reliable decontamination of radiological material. To keep the optic and laser system protected, a specialized casing is used to keep hazardous particles out of the optic, fiber, and laser system. The form-fitting case mates with the optic window and allows the operator to still have full functionality of the equipment without subjecting the optic to hazardous particles.

The nuclear-safe effiSCAN can be paired with our mid-power or CL1000 laser cleaning systems for applications including:

- General rust and paint cleaning

- Cleaning of weld seams for NDT

- Decontamination of metals and concrete

- Reducing fixed and loose surface contamination

WHATEVER YOUR NEEDS, ADAPT LASER HAS THE SOLUTION FOR IT

Adapt Laser specializes in providing the highest-quality laser cleaning systems available. Our systems come in both handheld and automated options making them versatile for different applications and surface preparation. We offer formal laser operations and safety training to ensure both you and your employees get the most out of their laser cleaning system. Over the past 15 years we have equipped numerous companies across varying industries with our state-of-the-art laser cleaning solutions.

If you’re looking for a faster, totally unique industrial cleaning and coating removal process, contact us today or call (816) 466-5855 to find the right laser cleaning system for you.

Like us on Facebook, connect with us on LinkedIn, and subscribe to us on YouTube