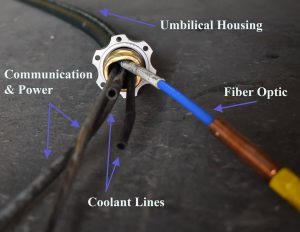

To supply lasers that function in different environments and offer full mobility, we’ve worked on optimizing protective housing for internal components. This includes the umbilical housing that holds the fiber optic, coolant supply, and signal cables. Our umbilical housing has stood out over competitors because of the advanced protection it offers—most specifically for the fragile fiber optic. But what exactly is the umbilical housing and what does it consist of?

UMBILICAL HOUSING BREAKDOWN

The umbilical housing is comprised of a multi-layer conduit with flexible structural metal, metal mesh, and a durable weather-resistant lining. It holds the internal components: the fiber optic, coolant supply, and signal cables safely in a cable package. The umbilical houses the fiber optic and cables in a way that maximizes overall protection to prevent breaks, kinks, and other general strain on them.

- Length: Standard =30 feet and can go up to 300 feet

- Location: coupled between resonator and the optic

- 6 lines: the fiber optic, communication, power, two coolant supply & return lines, and a compressed air line (not pictured)

WHY IS PROTECTION SO IMPORTANT?

Our fiber optics are made of quartz and carry the light that is transmitted though the laser. Because of this, the fiber optic needs to be well protected against outside forces, while still being flexible enough to move around when in operation.

It’s important that when installing the cable package or when operating the system, you always:

- keep a minimum bending radius

- never exposes the fiber and/or cable package to any kind of mechanical forces (tension, pressure, torsion, or bending)

Minimum Bending Radius:

CL20, Backpack, CL50, CL100 80mm 3.15”

CL150, CL300, CL500, CL600 250mm 9.84”

CL1000 320mm 12.60”

Even with the umbilical housing, it’s important that you keep forces to the cable package and fiber optic reduced to a minimum. If the minimum bending radius of your fiber optic is exceeded, you risk the potential of breaking the fiber optic. Proper usage, transportation, and storage can all help further the lifespan of your fiber optic.

WHAT HAPPENS IF YOUR FIBER OPTIC BREAKS?

Not only does the fiber optic have a strict minimum bending radius to remain within, but when a fiber optic does break, it will take some time to replace. Fiber swapping can be a tedious and time-consuming process, as the fiber optic must be aligned perfectly for the laser system to function.

While proper usage and good housekeeping play a part in keeping your fiber optic safe, we know that accidents will happen and are always a phone call away to help.

Since optics are delicate, they require both a trained service technician as well as a clean room for the fiber swapping process. If your fiber breaks, you’ll need to send your laser system in to our Kansas City office where we have a designated clean room for optical alignment. To help address the need for a faster replacement process, the Quick Disconnect was created. The Quick Disconnect—true to its name—eliminates the need for a clean room and for an intricate fiber alignment, allowing the user to swap fibers without having the expertise of a service technician.

WHY ADAPT?

We are continuously looking to supply our customers with laser cleaning systems with the best durability and lifespan. This includes all components ranging from the optic, resonator, chiller, umbilical housing, and more. Our umbilical housing unit has excelled when compared against competitor’s—whose design still includes plastic hosing, making the fiber optic less secure and more prone to damage. Our metal hosing, in contrast, is flexible enough to move around during laser cleaning, but rigid enough to maintain its protective qualities.

WHATEVER YOUR NEEDS, ADAPT LASER HAS THE SOLUTION FOR IT

Adapt Laser specializes in the know-how and application of laser cleaning solutions. We offer products with a range between 20 and 1,600 watts and provide training to ensure your employees can get the most from their laser cleaning solutions. We’ve equipped a variety of industries and companies with laser cleaning solutions — including military and defense for the US Air force and Navy — and hundreds of organizations trust our state-of-the-art laser cleaning solutions.

Contact us today or call (816) 466-5855 to find the right laser cleaning solution for you.