Whether it’s your first time working with one of our laser cleaning systems or you’ve had one in operation for years, we highly recommend having your operators attend our laser certification training. Led by one of our laser professionals, this training takes place on-site at the customer’s facility and typically spans 2-3 days. A tailored training schedule will be made to specifically match all of the areas of focus your operators will require based on the needs of your application, system, and facility. Ultimately, our goal is to ensure that your operators are knowledgeable on the operation, maintenance, and safe use of a class 4 laser system.

BENEFITS

- No travel on your team’s part is required

- See safety practices in real-time

- Watch basic maintenance demonstrations on your exact system

- Learn general troubleshooting tips and tricks

- Have your questions answered by a laser professional who operates these systems daily

- Ensure uniform training to employees

- An opportune time for employees to familiarize themselves with the laser system—being comfortable while operating is the key to success

LASER CLEANING TRAINING OVERVIEW

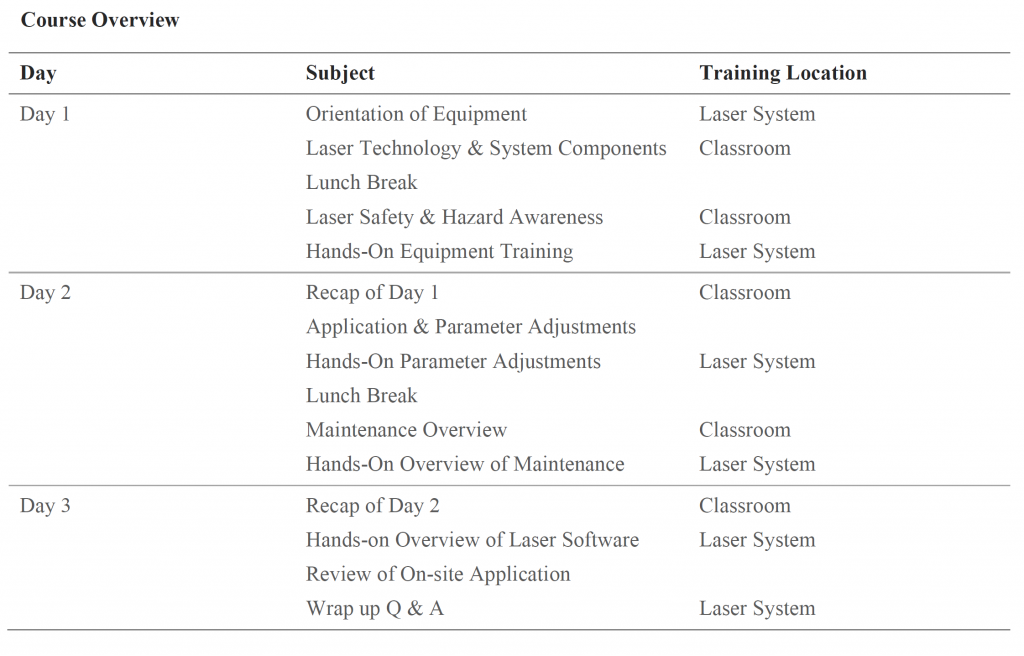

This month, one of our applications engineers travelled to a Michelin facility in South Carolina to perform our laser training to a group of 5 employees. While there, he followed our standard course of action which includes a mix of more traditional, in-classroom learning using powerpoints, videos, and educational animations as well as dedicated, hands-on sessions using the laser itself. A course overview will be offered, like the example below—all overviews are custom made to match facility, employee, and system needs.

CREDENTIALS

In order for us to provide this training, we are certified through the Board of Laser Safety, and have a designated employee who is our CLSO (certified laser safety officer). Our CLSO must complete annual training in order to remain compliant and has the task of educating, training, and testing all of our new employees on laser safety protocols and procedures.

We recommend checking your local OSHA (occupational safety and health administration) guidelines to see if your state requires a dedicated CLSO when using a class 4 laser.

1. LASER SAFETY TRAINING

Your trainer will start off by giving a little introduction of themselves and Adapt Laser before guiding the class through a crash course on laser terminology and components. This will cover the very basics on how cleaning lasers work, the systems that are currently available, and touches on the industries that we currently serve.

After learning about the very essentials of laser cleaning systems, we will turn to the first area of focus, which is on the big one—safety. Our training was designed in accordance to ANSI Z136.1 (American National Standard for Safe Use of Lasers) standards as well as the manufacturer’s instructions contained in the equipment user manual.

Specific Areas of Focus Include:

- Beam Related Hazards—Skin, eyes, and fire

- Non-Beam Related Hazards—Electrical and airborne contaminants

- Laser Safety Control Measures—Engineering controls, administrative controls, proper PPE, and establishing a LCA (laser controlled area)

- FAQs—We’ll field general FAQs along with any specific questions or concerns. Let us know ahead of the training and we can include certain topics that you want us to incorporate.

2. OPERATIONS TRAINING

Once we’ve covered safety and let the class get some hands-on experience with the laser, we turn to the fundamentals of operating the actual system. We’ll start with simply turning the system on and work our way through to how to set different parameters for certain applications.

Specific Areas of Focus Include:

- External Components—Filtration unit and compressed air

- Optic Control—Light indicator meanings, potentiometers adjustments, E-stop button location, pulling the trigger

- Remote Interface Requirements—Access to internet and remote access for cleanTOUCH

- Software Overview—cleanCONTROL

- Standard Applications—paint removal, rust removal, mold cleaning, strip cleaning, grounding contacts, pre-adhesive cleaning, pre-weld cleaning, post-weld cleaning, metallic substrates, and oxides

3. GENERAL MAINTENANCE

The last area of focus revolves around knowing how to properly maintain your laser cleaning system, including it’s different components. Although we do offer service/maintenance contracts for post-installation support, practicing proper preventative maintenance techniques from the very beginning is the best way to avoid most troubleshooting errors in the long run.

Specific Areas of Focus Include:

- Preventative Maintenance—Optics lens cleaning, protection from humidity, and biannual chiller maintenance

- Equipment Care—Cleaning a dirty optic protection window, draining and refilling the internal chiller, changing the water filter, swapping out the desiccant pack, protecting the fiber optic package and cable housing, and preventing beam reflection

- Troubleshooting Errors—Preventative maintenance will allow the operator to avoid most errors; many common errors can be found in the manual; general understanding of troubleshooting techniques typically helps identify the issue

COMPLETION

At the end of the course, the participants will be presented with a personalized certificate, verifying that they successfully completed our laser training. It’s important that any future operator of the laser, has been authorized in a similar fashion, before using the system. We offer refresher courses for any facility training new employees as well as a “train the trainer” course where the goal is to have an employee so proficient, that they can then teach the course to future operators.

Our team has travelled all over with the US and has even taught laser training courses in facilities in: Canada, Mexico, Germany, and Japan. We have the resources to travel to your facility, regardless of location.

WHATEVER YOUR NEEDS, ADAPT LASER HAS THE SOLUTION FOR IT

Adapt Laser specializes in providing the highest-quality laser cleaning systems available. Our systems come in both handheld and automated options making them versatile for different applications and surface preparation. We offer formal laser operations and safety training to ensure both you and your employees get the most out of their laser cleaning system. Over the past 15 years we have equipped numerous companies across varying industries with our state-of-the-art laser cleaning solutions.

If you’re looking for a faster, totally unique industrial cleaning and coating removal process, contact us today or call (816) 466-5855 to find the right laser cleaning system for you.

Like us on Facebook, connect with us on LinkedIn, and subscribe to us on YouTube