We are excited to be returning to exhibit at the RadWaste Summit 2.0 being held this year at the Louisville Marriott Downtown Hotel in Louisville, Kentucky. The RadWaste Summit is the must-attend event for professionals in high and low-level waste management and those in DOE Laboratory Leadership, offering invaluable insights and strategies to tackle industry challenges and advance environmental stewardship and national security objectives.

2024 RADWASTE SUMMIT 2.0 DETAILS:

WHEN: June 3-5th, 2024

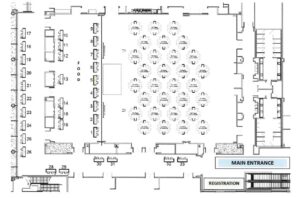

WHAT: Radwaste Summit 2.0 | 18th Annual Event | Waste Management Industry Experts WHERE: Louisville, KY | Louisville Marriott Downtown Hotel | Booth: #5

WHAT TO EXPECT

- Listen to a host of different speakers from the NNSA, the U.S. House of Representatives, the U.S. Senate, National Laboratories, the U.S. Department of Energy, the U.S. Department of Defense, contractors, and more.

- Chat with our sales team and learn about current and past clients who’ve experienced success when combining nuclear decontamination applications with our state-of-the-art laser cleaning systems.

- See the tradeshow’s full agenda with session times here.

- Register for the show here.

Nuclear Power Plant Aerial View

LASER ABLATION IN NUCLEAR DECONTAMINATION

With more than 440 nuclear power plants currently operating worldwide and 50 new plants currently under construction, there’s a rapidly growing need for nuclear decontamination processes. The costs to maintain and decommission these sites are often high and are extremely challenging to sustain. Laser ablation offers a more affordable alternative to media blasting and other traditional radiological decontamination processes due to its lack of secondary cleanup, environmental and operator friendliness, and low operating costs.

BENEFITS OF LASER CLEANING FOR NUCLEAR DECONTAMINATION

Laser Operator In Fukushima, Japan Post 2011 Earthquake

- Avoids equipment contamination using simple techniques

- Safe way to remove lead-based paints

- Capable of cleaning a wide range of materials

- Does not create radiological mixed waste

- Offers a new option to reduce dose rates

- Decontamination factor of up to 100%

- Reduces fixed and loose surface contamination

- Excellent for cleaning and surface prep for NDI testing

- Nearly zero harm to base material and surrounding equipment

- Produces a pure, clean surface for metal-to-metal contact for welding

Our laser cleaning systems can be handheld or automated making them ideal for on-site applications in the field as well as robotic, industrial setups. From helping to conduct hot tests in Fukushima, Japan after the devastating earthquake in 2011, to creating the gantry-based laser systems for fully automated decontamination, we have years of experience in nuclear decontamination.

WANT TO LEARN MORE ABOUT LASER CLEANING?

Adapt Laser specializes in providing the highest-quality laser cleaning systems available. Our systems come in both handheld and automated options making them versatile for different coating removal applications and surface preparation. We offer formal laser operations and safety training to ensure both you and your employees get the most out of the laser cleaning system. Our headquarters is in Kansas City, MO but we have sales managers across the country who can travel to your facility for an on-site demo. Over the past 21 years we have equipped numerous companies across varying industries with our state-of-the-art laser cleaning systems.

If you’re looking for a faster, totally unique industrial cleaning and coating removal process, contact us today or call (816) 466-5855 to find the right laser cleaning system for your application.

Like us on Facebook, connect with us on LinkedIn, and subscribe to us on YouTube