Laser ablation is the process of removing contaminants using thousands of laser pulses per second. But, how does it work? Why pulses? Wouldn’t a steady stream of laser light work more efficiently? Understanding what causes our laser solutions to work is the key to learning how to leverage its power for your cleaning, bonding, and pre-treatment purposes. And, with so many laser options available, it’s important to know the differences — including what makes it effective in the first place.

WHAT ARE CLEANING LASERS?

Lasers can be used for a variety of scenarios — from removing tumors to cutting sheet metal. But, not all lasers are the same. Think about the different types of vehicles. There are SUVs, sedans, and trucks, and while all accompany different needs, they’re equally considered vehicles. The same can be said for the variety of lasers. Each has its own purpose and a different outcome.

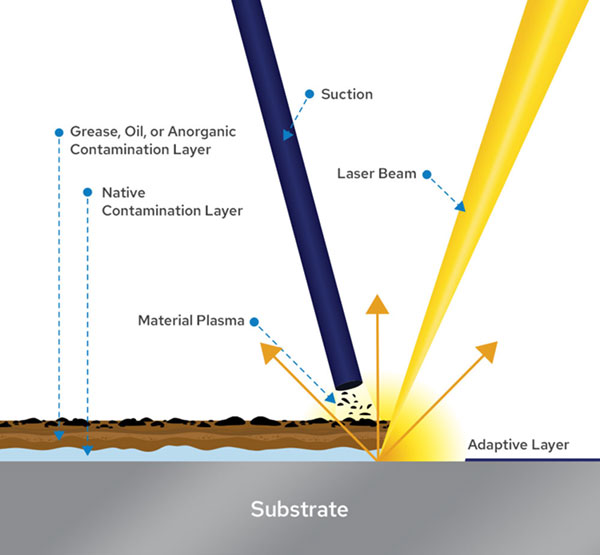

When referring to cleaning lasers, we’re talking about the process known as laser ablation. During laser ablation, optics shape the laser beam, and the laser light absorbs into and removes contaminants from a targeted surface. It does this with thousands of pulses per second. As you move the laser, it safely and effectively removes contaminants — but the integrity of your product remains unharmed. The laser system cleans three different ways: pulsing, scanning, and moving.

PULSING

In our lasers, pulsing occurs at the laser source and then travels through the fiber to the scanner. This is the most effective way to clean and remove contaminants. Pulsing cleans a very targeted area of your product, and the effect can be illustrated with a gardening hose. With the faucet turned on, you get free-flowing water. But, put your thumb over the hole just right, and the water is forced out at an accelerated speed. Now, imagine covering and uncovering the hose a thousand times per second — if, in theory, that was possible. The result creates a vast amount of energy per pulse and the high-powered water forces its way out of the gardening hose.

That’s how pulsing works. By creating lots of energy in short, controlled pulses, you get an incredibly powerful cleaning tool. But, the damage threshold is never crossed, unless desired, so the integrity of your product is protected — leaving behind a pristine surface only.

SCANNING

As the pulses enter the optics, the scanner will use internal mirrors to guide the pulses across the surface — either a one-dimensional line or a two-dimensional shape. The scan speed of the laser system and the speed at which the pulses are guided across the shape can create the desired effect by overlapping or spacing these pulses out. When using our handheld optics, the scanner is moving the pulses back and forth. But, by using a two-dimensional optic, there are two-dimensional overlaps to consider across the shape for the desired effect.

The scan speed settings directly impact your scanning. Some products will need a quicker speed for more overlapping, while others will be cleaned with less overlap or gaps in the pulses. Depending on the product, you may need heavily overlapping pulses to get the desired surface alteration, whereas another application can achieve the desired quality by spacing the pulses out. The scanner settings allow us to make that decision. The scan type, intensity, speed, and optics are all determined on a per-product basis during the sales process.

MOVING

To clean an entire targeted area, the laser solution will need to move. By moving the optic or part relative to the laser to clean, you’ll remove contaminants from the entire desired area. There are a variety of options that impact what needs to move, including:

- Handheld

- Enclosed

- Robotic

If you’re using a handheld laser system, then you’ll have more freedom over which areas to target for cleaning. In comparison, an enclosed laser system is typically completing small part automated cleaning via a gantry or smaller robot inside. You’ll have to put your product inside the enclosed system before it can automatically be cleaned. By attaching your laser to a large robotic setup — whether enclosed or not — you have the option to do a little of both.

The type of product you’re cleaning — as well as these use cases — are all discussed during the sales process. Since our laser solutions are built specifically for your needs, you’ll get the solution that works best for your cleaning project. Whether it’s handheld or automated, you’ll have the right cleaning system for the job.

WHATEVER YOUR NEEDS, ADAPT LASER HAS A SOLUTION FOR IT

Adapt Laser specializes in the know-how and application of laser cleaning solutions. We offer products with a range between 20 and 1,600 watts and provide training to ensure your employees can get the most from their laser cleaning solutions. We’ve equipped a variety of industries and companies with laser cleaning solutions — including military and defense for the US Airforce and Navy — and hundreds of organizations trust our state-of-the-art laser cleaning solutions.

Contact us today or call (816) 466-5855 to find the right laser cleaning solution for you.