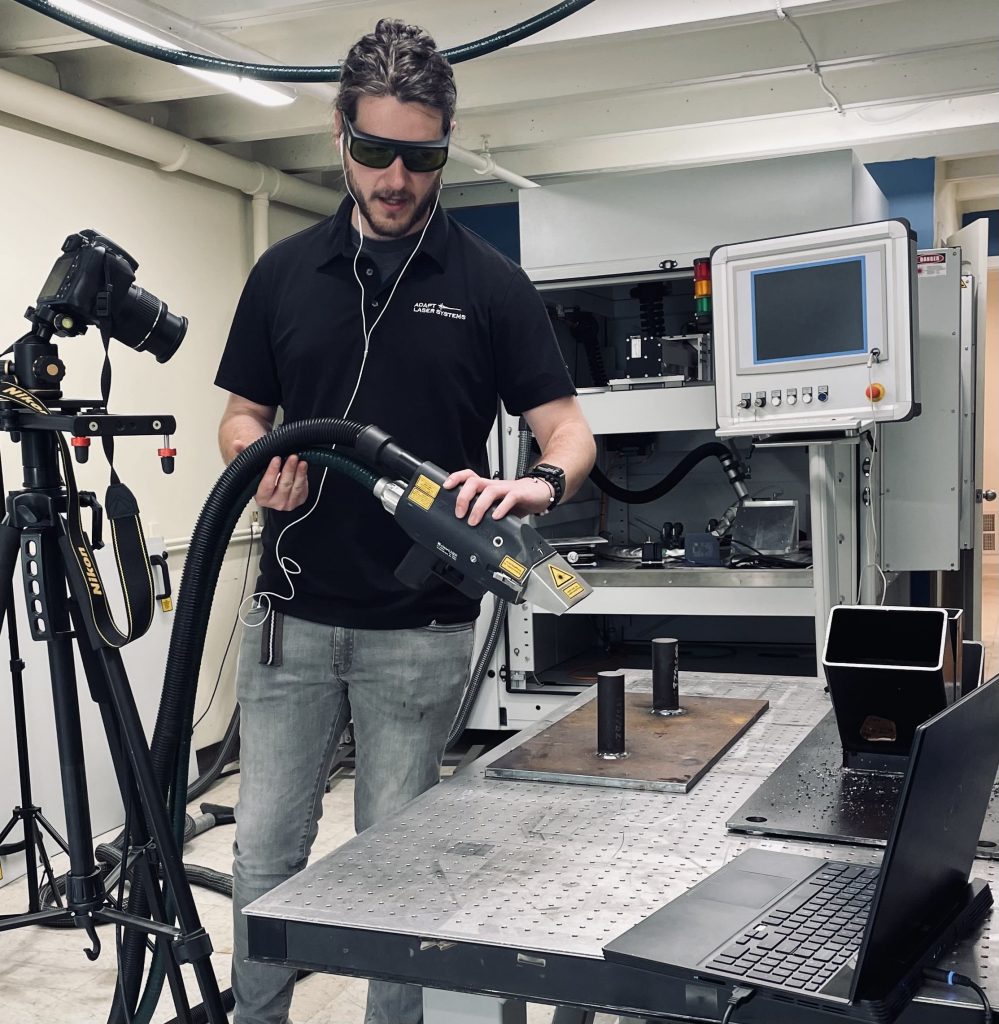

Virtual Lab Benefits

Since opening our doors at our Kansas City location, we’ve invited customers to come and do an on-site visit to our applications lab as a first step to purchasing a laser cleaning system. When COVID-19 limited travel and forced many companies to close their doors to the public, we knew we had to quickly implement […]

Laser Cleaning for Fiberglass Molds

Laser ablation is one of the best cleaning solutions for metal molds. It effectively removes sticky and thick contaminants for uniform results, time and time again. Not only can laser systems be automated to promote mass production, but they’re also quicker than some abrasive alternatives. But, are laser cleaning solutions the most practical and effective […]

Safe, Non-Toxic Hazardous Coating Removal Alternative

Laser cleaning technology is considered one of the safest alternatives for hazardous coating removal, bonding and welding treatment, and other contaminant removal processes. That’s because laser ablation requires very little PPE and makes disposal of hazardous waste a breeze. But, what makes it so safe? And, why is it the ideal solution for most hazardous coating removal? […]

Common Aerospace Cleaning Mistakes

Performance and reliability are the backbone of the aerospace industry. Oftentimes, however, methods of cleaning aircraft and preparing them for coating and bonding are stuck in the past. Despite being at the cutting edge of flight technology, many aerospace companies have failed to take advantage of modern advances in parts cleaning that can save them […]

Things That Impact a Fume Extraction Filter Unit Purchase

If you have a laser application — whether for cleaning or etching — you need a fume extraction filter unit. That’s because these powerful filtration systems make it safer for you to operate your laser. During the laser cleaning process, hazardous contaminants are safely absorbed and captured by the filter unit. This prevents dangerous chemicals […]

The True Cost of Remote Support

When you purchase a laser solution from Adapt Laser, you’re also offered the opportunity for remote support services. How quickly or often you get this support is based on your unique needs and is typically outlined in your contract. The more support you need, the more you’ll likely pay, but the true cost of remote […]

Common Automotive Cleaning Mistakes

6 COMMON AUTOMOTIVE CLEANING MISTAKES 1. TAKING SHORTCUTS In a production environment where small savings can add up quickly, it’s tempting for manufacturers to look for the cheapest, quickest result. Unfortunately, things that seem cost-effective in the moment can have unintended consequences down the road. In the case of cleaning, shortcuts don’t always pay off. […]

Alternative to Needle Guns

When it comes to removing layers of contaminant or coatings from parts and equipment, effectiveness is often the primary determining factor. Questions of efficiency, cost, and ease-of-use often come later. If you can find a solution that gets the job done and provides added benefits, it can be a game changer for your entire operation. One of […]

Hexavalent Chromium Removal

Hexavalent chromium may not be a household name for most, but for those in the aerospace and military industries, it’s hard to avoid. The specialized parts and equipment used in each of these industries require special coatings to ensure performance and longevity. However, an unfortunate side effect of these compounds is that many of them […]

Selecting Your Supporting Optics

A laser point of emission is the source of your laser cleaning solution, which is why it’s so important that you have the correct supporting optics for your needs. Often, cookie-cutter laser cleaning solutions — also known as off-the-shelf solutions — will use one optic that may or may not be right for your project. […]