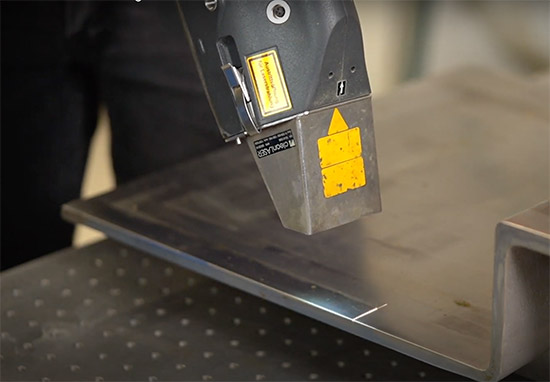

Custom Laser Cleaning Systems

DESIGNING A CUSTOM LASER CLEANING SOLUTION

PROJECT SPECIFICATIONS AND REQUIREMENTS

Our custom laser solutions are built specifically for your project. To determine which application will work optimally, we’ll ask you a variety of questions regarding your project and what you’re looking to accomplish, including:

- General size, area, and geometry of the parts needing to be cleaned

- Material substrate(s)

- Coating/contaminant type and thickness

- Current cleaning type, rate, and cycle

- Desired cleaning rate

- Previous processing steps in the part lifecycle

- Next steps after cleaning

- Operational details surrounding the laser process

Once we know your initial requirements, we’ll test your product in our lab to determine the right laser for your needs — both from a technical and operational standpoint. Our goal is to help you accomplish the desired result. To find the right laser cleaning system for your needs, contact our team to begin the sales process.

LOW-POWER LASER SOLUTIONS

Low-power doesn’t equate to ineffective. In fact, our low-power laser solutions provide a gentle, high-precision cleaning perfect for historic restoration, de-coating, and small treatment areas. It uses short pulses of laser light and has the same intensity as other powered cleaners, but is ideal for products such as:

- Historic buildings

- Small automotive parts

- Rubber/Injection molds

- Military equipment — for bonding and welding treatments

- Any application where gentle cleaning is required

MID-POWER LASER SOLUTIONS

Our mid-power laser has a quicker cleaning rate and allows for larger surface area cleaning. From mobile to stationary options, our mid-power laser solutions are beam-delivered up to 300 feet away and user-friendly. Each laser is controlled from their supporting optics system and is perfect for:

- Oxide or lubricant removal prior to welding

- Targeted corrosion removal on aircraft wings

- Composite and tire molds

- Historic restoration

- Paint removal on aircraft

HIGH-POWER LASER SOLUTIONS

From handheld to automated, our high-power laser solutions are some of the most powerful on the market and are beam delivered, allowing them to be used up to 300 feet away. The application is easy to use and features a touch-screen display and real-time controls. It safely produces larger amounts of energy per pulse of laser light, making it ideal for industrial use and:

- Eliminating corrosion from metals

- Hazardous coating removal

- Pre-treatment of welding seams

- Nuclear decontamination

- Cleaning prior to NDI

LASER SYSTEM COMPONENTS

When it comes to customizing specific features of a cleaning laser, we consider several components to make sure the laser is well-suited for the job. The most common include:

- Fiber— our laser solutions use a fiber-fiber coupling, but the length and size of these fibers can impact beam shape

- Optics — flat-top or Gaussian? 1-D or 2-D? Optics customizations can be highly specialized to meet the specific requirements for your project

- Delivery system — handheld or automated? If you’re performing repeated tasks or need a mobile cleaning solution, this choice can determine what kind of laser system fits your operations

- Fume extraction — what fumes and particles are being produced by the cleaning? What fume extraction filter unit works well for a small rust removal project will inevitably differ from what is best for nuclear decontamination

- Special functionality requirements — does your laser need additional parts customization for the project?