Your Guide to Laser Cleaning Terminology

Buying a laser cleaning solution means learning all new terminology. From optics and window protection to comparing COTS and developed solutions, understanding complex terms are the first step toward making an informed decision when it comes to building and operating your laser system. That’s why we’ve created a comprehensive list of the most common laser […]

5 Laser Application Add-Ons You Need for Your Solution

During the custom-build process for your laser system, we consider every use to ensure your system works optimally for your environmental and operational needs. And, while not all add-ons are necessary for your laser to work effectively, there are some to consider adding that will create an easier experience and make it quicker to troubleshoot […]

Laser Cleaning as an Alternative to Sandblasting

Sandblasting has long since been considered an effective way to clean surface areas, but did you know that laser cleaning is a safer and less damaging alternative to sandblasting? Whereas sandblasting can damage the substrate you’re trying to clean, laser cleaning provides a non-damaging cleaning option that can actually extend the lifespan of the equipment […]

Laser Cleaning vs Sandblasting

Oxygen is essential to life — it makes up the air we breathe, helps spark fires, and contributes to plant growth. While oxygen is incredibly beneficial and crucial to the survival of mankind, it also plays a role in breaking down or corroding metal objects. This occurs through a process called oxidation, and it results […]

Troubleshooting Your Laser Cooling System

Temperature widely impacts the performance of your laser solution — whether it’s from operational or environmental causes. That’s why each mid- and high-power laser solution (which generates more energy and therefore more heat) is customized and designed to include a water chiller to help keep your system cool and running as expected. But, as with […]

When Should You Change Your Laser Air Filter?

Your laser solutions require daily, monthly, and, sometimes, yearly maintenance. From changing the desiccant packs to monitoring the window protection, there are a few items to stay diligent with. While some parts can easily be cleaned for maintenance, other pieces need replacing. Such is the case with air filters. What happens if your air filter […]

3 Signs Your Laser Solution is Overheating

From a humid, outdoor working area to a cool, air-conditioned room inside, our laser solutions are designed to function in a range of environments. Yet, despite being designed for a range of elements, failing to maintain the system can cause the laser system to become damaged. As with other tools, our laser systems require some […]

3 Things You Need From a Laser Cleaning Provider

Realizing that a laser solution would be an ideal alternative for your cleaning needs is only part of the process. The next step is finding a laser cleaning solutions provider that can support your needs, shares similar values, and is a partner that you can trust. As with any service provider, not all companies are […]

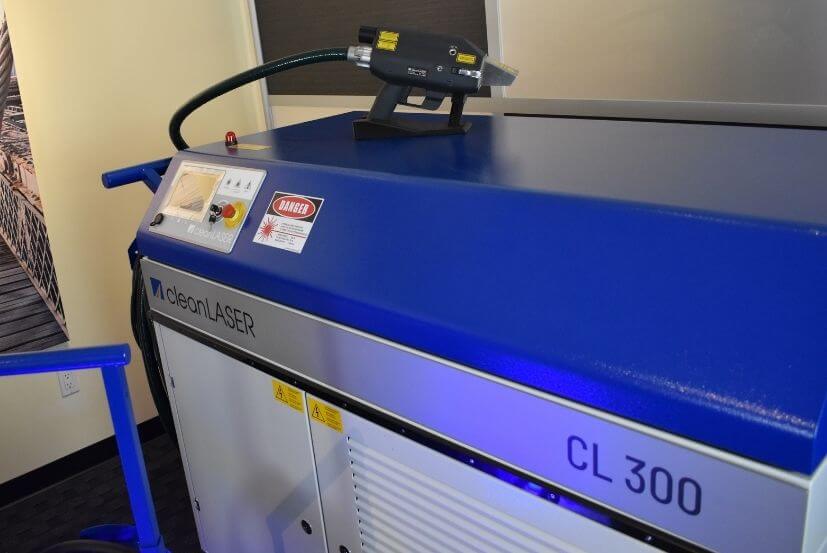

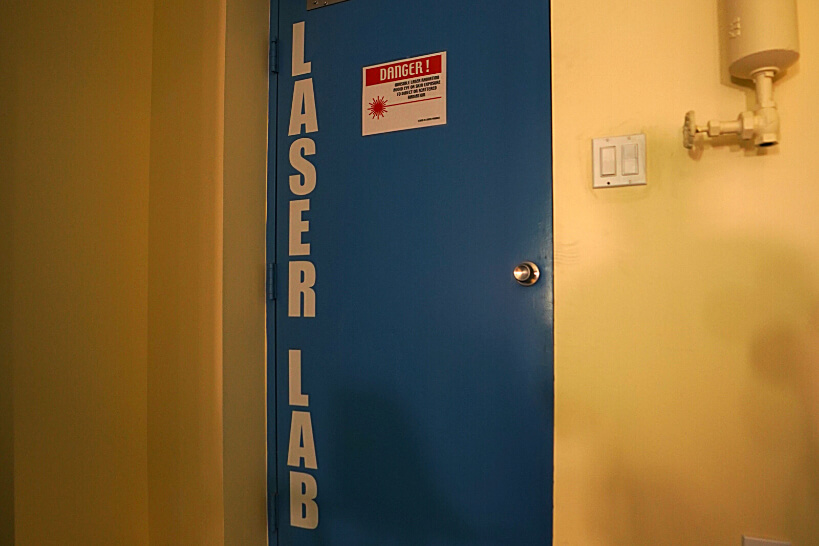

Questions Answered During Our Lab Testing

Before you’re ready to use your laser solution — and prior to it being customized to fit your needs — your product must first be tested in our on-site lab. Our lab testing is proven to identify whether or not laser cleaning is the right solution for your needs and which laser system is best […]

What’s Intensity & How Does It Impact Your Laser?

When deciding whether or not you want to purchase a laser cleaning solution, you’re likely to do research. During that research, you may learn about different jargon that comes with the territory. This includes terms such as pulses, optics, and intensity. While it’s easier to connect some words — like pulses — with their normal meaning, words […]