Adapt Laser To Exhibit At Warrior West 2022

WARRIOR WEST EXPO WHAT: The Defense Industry’s Top Expo | For Networking, Training, And Product Demos WHERE: San Diego Convention Center in San Diego, CA—Booth Number: TBA WHEN: April 27th-28th, 2022 PRESENTED BY: ADS Inc Warrior West Expo is designed to equip the warfighter with advanced capabilities to optimize performance and improve readiness, while increasing […]

Adapt Laser To Exhibit At The WM Sym 2022

WM SYMPOSIA 2022 DETAILS: WHAT: WM Symposia 2022 | 48th Annual | 900+ Presentations | Representing 35 Countries WHEN: March 6th-10th, 2022 WHERE: Phoenix, Arizona—3rd floor of the PCC North Building, Halls A-D—Booth 633 HOSTED BY: WM Symposia Inc—a non-profit organization dedicated to providing education and information exchange on global radioactive waste management. THIS YEAR […]

Abrasive Blasting Vs Laser Ablation

Although abrasive blasting goes by other names—such as sandblasting, media blasting, and grit blasting—all of them refer to the process that involves forcibly propelling a stream of abrasive material against a surface to clean or modify its properties. This method has been used for many years and works with a variety of applications including surface […]

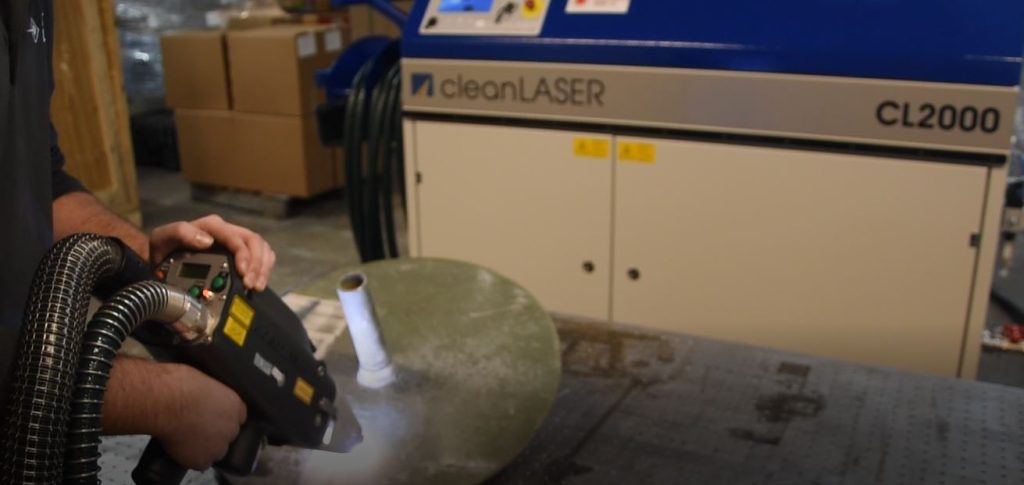

Product Highlight: The Powerful CL2000

THE CL2000 “A LASER CLEANING SYSTEM FOR INDUSTRIAL APPLICATIONS” Our CL2000 is a versatile, industrial laser cleaning system that’s the culmination of 20+ years of laser cleaning expertise between us and our German-based partners at cleanLASER. With an almost identical design to the CL1000, it includes many of the same key features that has made […]

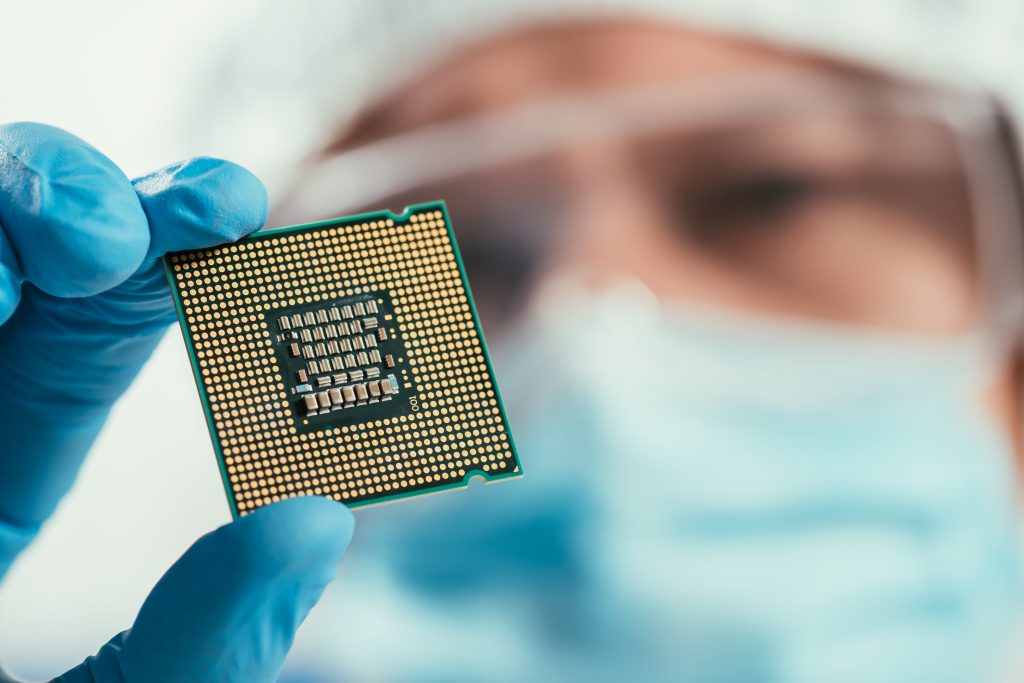

PVD Coating Removal Via Laser Ablation

Although specific benefits vary by process, PVD coatings are growing more popular in aerospace, military, automotive, energy, food processing, and other large manufacturing industries where there is a big emphasis on durability and longevity. With heat-resistant and friction reducing capabilities, PVD coatings are ideal for high-end products, decorative finishes, semi-conductors, and medical devices. WHAT IS […]

Variety of Optics: Automated

Our variety of powerful, highly dynamic optics all come integrated with scanning systems that allow for both handheld and automated applications. Because the optics ablate by distributing thousands of powerful pulses onto the substrate’s surface to sublimate the contaminant(s), it’s extremely important to use the correct optic for an effective clean as well as to […]

Co-Exhibiting At The World Nuclear Exhibition 2021

WNE 2021 DETAILS: WHAT: World Nuclear Exhibition | 550 Exhibitors | 18,000+ Participants | 55 Countries WHERE: Paris, France—Paris Nord Villepinte – Hall 7 – Booth B68 WHEN: November 30th-December 2nd 2021 WHO: Join us and our partners cleanLASER, Meliad, and Loop We’re excited to be attending our first major tradeshow since the beginning of […]

Media Blasting To Ablation: FRCE’s Integration of Lasers

Last year we were contacted by engineers at Fleet Readiness Center East who have been working to bring laser ablation technology into their facility for some time now. Their Advanced Technology and Innovation Team and Materials Engineering Division have been specifically looking for a faster, safer, and more cost-effective approach to the media blasting processes […]

Variety of Optics: Handheld

The optic is the end effector of the laser and is what is used to transmit and manipulate the laser beam. Using the right optic is important, as having the wrong one or using it improperly can result in an inefficient clean and can be harmful to the substrate, the operator, and the environment. Our […]

The effiSCAN: An Ultra-Compact Optic

NEWEST HANDHELD OPTIC: The effiSCAN Along with our partners at cleanLASER, we’re continuously using customer feedback and advances in technology to update our laser cleaning systems to make them more operator-friendly and versatile. This extends to our optics, where one area of focus surrounded the size of the optic head itself, and how easy it […]