Laser Cleaning Training: On-Site

Whether it’s your first time working with one of our laser cleaning systems or you’ve had one in operation for years, we highly recommend having your operators attend our laser certification training. Led by one of our laser professionals, this training takes place on-site at the customer’s facility and typically spans 2-3 days. A tailored […]

Superior Filtration: TEKA’s LFE 401

During the laser cleaning process, the material you’re ablating will become airborne contaminants—allowing microbes and other dangerous particles to escape into the surrounding environment. In order to properly catch, store, and dispose of these particles and fumes, you’ll need a high-quality fume extraction system. Our partnership with TEKA grants us access to the best fume […]

Adapt Laser’s CL600 is Navy-Approved

Last week, the Department of Defense released a memorandum approving the use of our CL600 laser cleaning system on non-nuclear ships and extending a limited approval for in-service aircraft carrier applications and de-activated aircraft carrier applications and submarines. The private memorandum included sections summarizing the background, discussion, reports and testing, recommendations, ongoing and future work […]

100W lightCASE: Corrosion Removal In High Places

THE CHALLENGE To laser clean an active chiller that had developed a large amount of corrosion—enough to question the integrity of the underlying metal—prior to inspection and repair. The problem? This particular chiller was located on the 57th floor of a downtown Charlotte, North Carolina high-rise and included a lengthy amount of overhead work in […]

Historic Conservation of Bronze War Statue

In the town of Westfield, Massachusetts stands the statue of General William Shephard—a United States Representative and military officer—who protected the Springfield Armory during Shay’s Rebellion in the height of the Revolutionary War. Over the years, Shephard’s statue along with others in the area, had began to build up large amounts of corrosion making it […]

Superior Suction: Interchangeable Nozzles

One of the biggest advantages laser cleaning has over its more traditional competitor—media blasting—is its lack of cleanup and coinciding environmental friendliness. Our ablation process involves suction and filtration as the method of capture and disposal for contaminants, and we take special consideration for hazardous gases and fumes. But how can suction options differ and […]

Post-Installation Support

Like any other large piece of machinery, your laser cleaning system will need routine servicing and general maintenance to ensure optimal performance. To help with this, we take our post-installation support seriously and have tailored service contracts that include guaranteed response times and critical spares on-site. Because not all companies need the same level of […]

The Quick Disconnect Feature

Until recently, a broken fiber optic would mean an immediate and unavoidable cease in laser operations. Your laser cleaning system would be out of commission until one of our trained laser service technicians could perform a fiber swap. Due to the fiber optic’s fragility, a fiber swap can take upwards of 10 hours—even when done […]

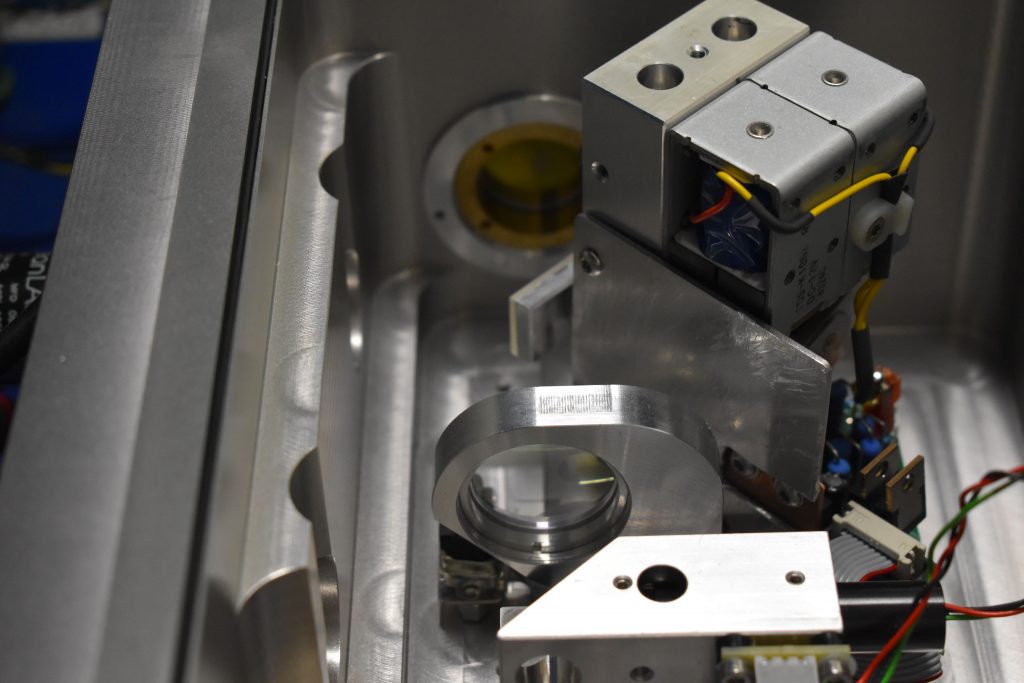

Beam Switch: Two Optics, One Resonator

Depending on your application, your laser cleaning system will operate using either a handheld or an automated optic. Both optics have their own benefits and limitations, and determining the right optic will be important to get the best treatment for your substrate. Handheld optics offer advanced mobility and allow you to adjust and maneuver around […]

Umbilical Housing Breakdown

To supply lasers that function in different environments and offer full mobility, we’ve worked on optimizing protective housing for internal components. This includes the umbilical housing that holds the fiber optic, coolant supply, and signal cables. Our umbilical housing has stood out over competitors because of the advanced protection it offers—most specifically for the fragile […]