How Does Fume Extraction Work?

No matter your laser solution — whether it’s for cutting metal and etching, tattoo removal, or safely removing contaminants — your process can result in fumes, particles, dust, and hazardous chemicals becoming airborne. To prevent these dangerous microparticles and gases from impacting your operators or the environment, your laser solution needs a powerful filter to […]

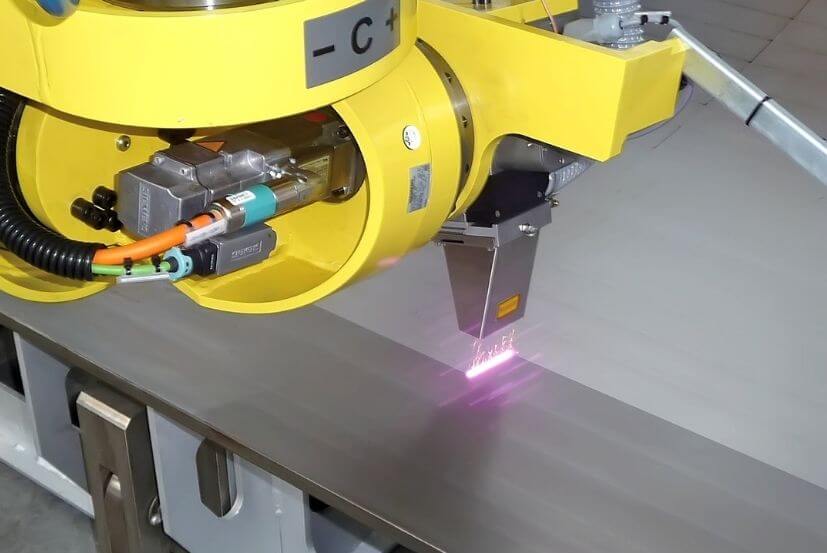

Laser Wire Stripping

In the world of electric vehicles, it is often the sleek designs and high-tech accoutrements that catch the eye of the public. However, one of the more exciting recent developments in electric car manufacturing is something often hidden to the casual consumer — improvements in wire stripping. Laser ablation technology is now being used to […]

U.S. Air Force Laser Cleaning

Vehicles and equipment in the US Air Force face a grueling existence. They are placed in the most extreme conditions and expected to perform with both strength and reliability, time and time again. Maintaining and servicing these vital aircraft and equipment, therefore, is no small task. When the time comes to remove those layers of […]

What is Laser Back Reflection & How Does It Impact Your Laser?

Laser ablation is one of the safest and most effective methods for cleaning products and prepping surfaces for bonding, welding, and coating. But, there are still some safety precautions that must take place when operating your laser solution. This includes laser safety glasses, participating in training, and creating a designated optical hazard zone. The reason […]

Buying Guide for Fume Extractor Filters

Fume extractors are essential for safely removing hazardous chemicals and other contaminants from your products. But, not all filter units are made the same. As the exclusive provider of TEKA filters in North America, Adapt Laser provides quality fume extractor filter units for your laser processing solutions. But, what makes them different? What are your […]

Tips for Meeting OSHA Laser Cleaner Requirements

When you purchase a laser cleaning solution from Adapt Laser, you’re required to appoint a laser safety officer. This person is responsible for ensuring that training occurs and that all safety regulations are met. One such standard is a yearly review required by the Occupational Safety and Health Administration (OSHA). During this review, they’ll monitor how well […]

How To: Changing Laser Cleaning Locations

Your laser solution has been specially designed to operate most effectively in a particular environment. Whether you chose your designated optical zone to be in a temperature-controlled room where you could easily integrate locking mechanisms or you primarily operate behind laser safety curtains in a warehouse, the effectiveness of your laser solution relies on the […]

Evolution of Laser Cleaning Technology

Laser cleaning is the best option for removing contaminants safely and effectively from most metals and several non-metal products. It can be used to stop corrosion, treat products pre- and post-weld processes, remove hazardous coatings, and more. But, laser cleaning technology has come a long way since 1973 when J.F. Asmus first proposed that lasers […]

Laser Cleaning for Non-Metal Products

From the US military to automotive manufacturing plants, laser ablation technology is trusted to deliver effective cleaning results. Most of the time, these projects involve cleaning rust, coating, and other contaminants from hard metal substrates. What you may not realize, however, is that laser cleaning can also be used for some non-metal surfaces as well. […]

Laser Cleaning Petroglyphs

Laser cleaning technology has been used for various products — from metals like steel and aluminum to non-metals like stone and other historic restoration projects. But, laser ablation isn’t a suitable method for every scenario where cleaning is needed. One area that has become a learning curve are non-metal historical objects. Our laser solutions have […]